UK-based transport engineering consultancy Ricardo has revealed that it is currently involved with major truck platooning R&D and demonstration projects in Europe, Asia and North America, paving the way for the future use of automated freight convoys.

Ricardo is one of the companies leading the way in bringing the prospect of heavy-duty long-haul truck platooning to the world’s highways, with the technology offering the prospect of CO₂ emissions reductions and operator fuel savings, while improving traffic flow and road safety.

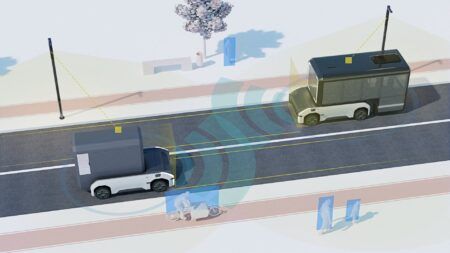

In addition to their ongoing R&D and demonstration programs, Ricardo’s connected and automated vehicle (CAV) experts were actively involved in the recently completed EcoTwin III truck platooning project. This European research initiative successfully developed technology for a robust three-truck platooning system enabling an inter-vehicle time gap for the platooned trucks of 0.3 seconds or less, equating to 23ft at 50mph (7m at 80km/h), which is both functionally and operationally safe.

Although the EcoTwin III project concluded in late 2017, the Ricardo project team has continued to build upon the results in the crucial areas of functional safety and the development of platooning control software. In its platooning safety work, the company has further developed processes for CAVs using a modified approach based on the ISO 26262 automotive functional safety standard. In doing so, the safety case approach has also been deepened to demonstrate the required level of complexity for CAV safety in the context of platooning. Ricardo has also developed a deeper understanding of the requirements of highways authorities for CAV road exemptions.

Ricardo has also continued to develop its PCAMS (Platooning Control Algorithms, Model and Simulation) software that provides a ‘whitebox’ system that is adaptable for platoon-lead and following-vehicle control using camera/radar and V2V (vehicle-to-vehicle) data. The system enables a stable inter-vehicle gap size to be maintained, and ensures the string stability of the platoon. The PCAMS software is based on the original work Ricardo led in the European Commission-sponsored H2020 SARTRE program and through various follow-on platooning projects in Europe and North America.

“Platooning offers an opportunity to improve the safety of truck transportation, reduce CO₂ emissions and operator fuel costs, while also reducing the demands placed upon truck drivers,” explained Ricardo vehicle automation and safety specialist, Richard Saady.

“This is probably one of the closest to market CAV applications, and one that offers tangible environmental, commercial and safety benefits. We are pleased therefore to be developing some of the enabling technologies and participating in collaborative R&D programs, aimed at bringing the benefits of this technology to the world’s highways.”